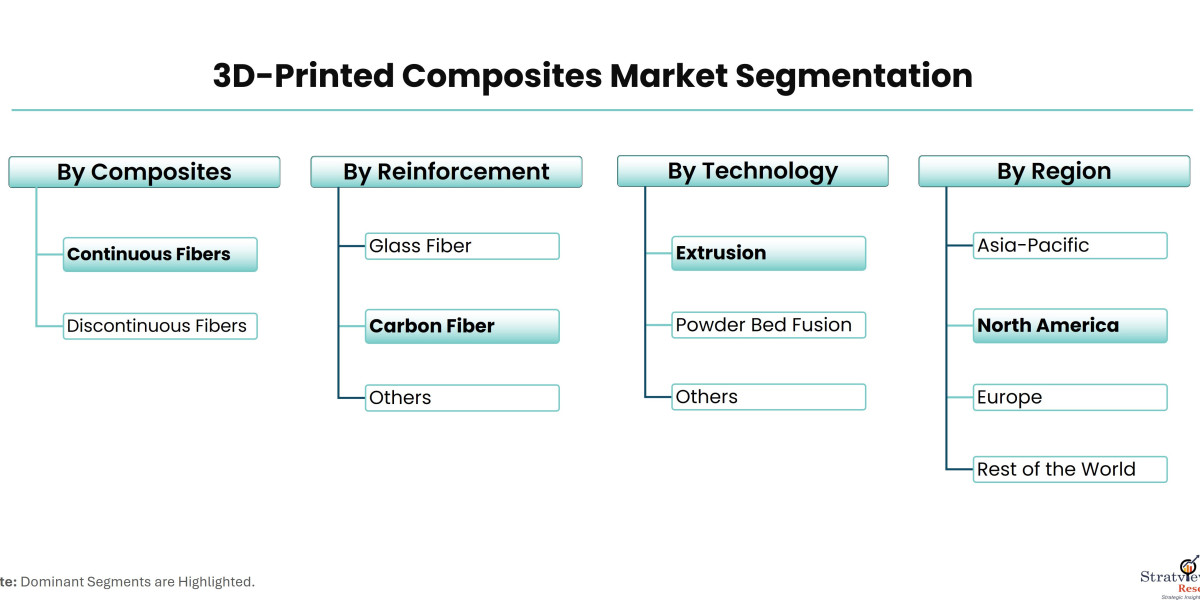

According to Stratview Research, the 3D-printed composites market is projected to grow at an impressive rate in the coming five years to reach an estimated value of USD 187.7 million in 2024.

In recent years, the intersection of 3D printing technology and composite materials has sparked a revolution across industries. This fusion has unlocked new possibilities in manufacturing, design, and material engineering, offering a glimpse into the future of production. In this article, we delve into the burgeoning 3D-printed composites market, exploring its transformative potential and the opportunities it presents.

The Rise of 3D-Printed Composites: Traditional manufacturing methods often face limitations in producing complex geometries with conventional materials. However, the advent of 3D printing has shattered these constraints by enabling the layer-by-layer deposition of materials, leading to the creation of intricate structures previously deemed impractical or impossible.

Composites, renowned for their strength-to-weight ratio and versatility, have long been utilized in various industries, including aerospace, automotive, healthcare, and consumer goods. Combining the advantages of composites with the additive manufacturing capabilities of 3D printing has opened up a realm of innovation.

Unlocking Innovation: One of the primary drivers behind the adoption of 3D-printed composites is the ability to customize components according to specific requirements. Designers and engineers can tailor material properties, such as stiffness, strength, and flexibility, to meet the demands of diverse applications. This level of customization empowers industries to optimize performance while minimizing material waste—a significant advantage in today's environmentally conscious landscape.

Furthermore, 3D printing offers unparalleled design freedom, allowing for the creation of complex shapes and intricate internal structures that enhance functionality and performance. This capability is particularly advantageous in industries where lightweight, high-strength components are paramount, such as aerospace and automotive manufacturing.

Applications Across Industries: The versatility of 3D-printed composites has led to their widespread adoption across various sectors. In aerospace, lightweight components are crucial for fuel efficiency and performance. Manufacturers are leveraging 3D-printed composites to produce aircraft parts with reduced weight, leading to lower operational costs and enhanced sustainability.

In the automotive industry, 3D-printed composites are revolutionizing vehicle design and performance. From lightweight body panels to structural components, these advanced materials offer automakers the opportunity to improve fuel efficiency, durability, and safety while reducing vehicle weight.

Moreover, the medical field is harnessing the potential of 3D-printed composites to fabricate patient-specific implants, prosthetics, and medical devices. The ability to create customized, biocompatible structures tailored to individual patients' needs marks a significant advancement in healthcare technology.

Challenges and Opportunities: While the 3D-printed composites market holds immense promise, it is not without its challenges. Material selection, process optimization, and quality control remain critical considerations for manufacturers seeking to capitalize on this technology. Additionally, scalability and cost-effectiveness are areas that require further development to fully realize the market's potential.

However, despite these challenges, the opportunities presented by 3D-printed composites are undeniable. As research and development efforts continue to advance, we can expect to see further innovation in materials, processes, and applications, driving growth and evolution within the market.

Conclusion: The convergence of 3D printing and composite materials heralds a new era of manufacturing, where customization, efficiency, and performance converge to shape the future of production. The 3D-printed composites market is poised for exponential growth, offering transformative solutions across industries and unlocking boundless possibilities. As we continue to explore this dynamic field, one thing is clear: the future of manufacturing is here, and it's built on 3D-printed composites.