In this article, we'll explore the key components and benefits of an OEE dashboard and how it helps drive continuous improvement in manufacturing operations.

What is OEE?

Before diving into the specifics of an OEE dashboard, let's briefly discuss what OEE is and why it's important. OEE is a metric OEE Dashboard commonly used in manufacturing to measure the effectiveness of equipment and processes. It takes into account three primary factors:

Availability: The percentage of time that equipment is available for production.

Performance: The speed at which equipment operates compared to its maximum designed speed.

Quality: The percentage of good-quality products produced by the equipment.

By combining these factors, OEE provides a comprehensive view of how well equipment is performing relative to its full potential. A high OEE indicates efficient, reliable, and productive operations, while a low OEE suggests opportunities for improvement.

Components of an OEE Dashboard

An OEE dashboard typically consists of several key components designed to provide a clear and concise overview of equipment performance. These components may include:

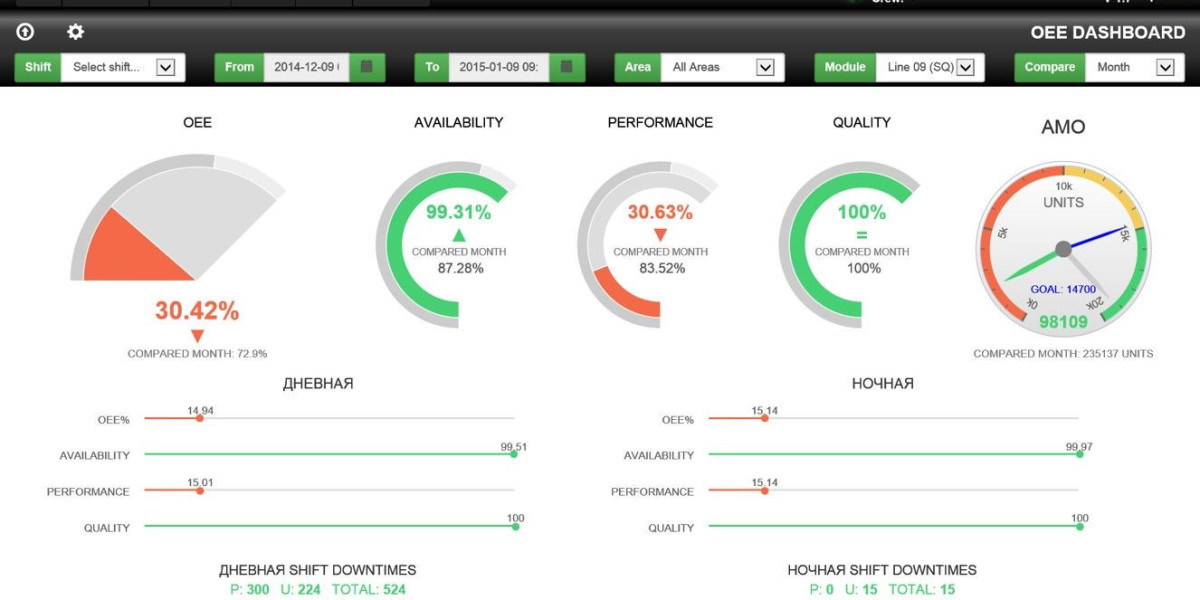

Overall OEE: A summary metric representing the overall effectiveness of equipment and processes. It gives managers a quick snapshot of performance across multiple metrics.

Availability, Performance, and Quality Metrics: Detailed breakdowns of each component of OEE, allowing managers to identify specific areas for improvement. These metrics may be presented graphically to highlight trends over time.

Downtime Analysis: Information on the reasons for equipment downtime, such as mechanical failures, setup and changeover times, and maintenance activities. Understanding the root causes of downtime is crucial for implementing targeted improvements.

Production Output: Real-time data on production output, including the number of units produced, cycle times, and production rates. This information helps managers track progress towards production targets and identify potential bottlenecks.

Quality Control: Metrics related to product quality, such as defect rates, rework levels, and scrap rates. Monitoring quality performance allows managers to take corrective actions to minimize defects and improve overall product quality.

Performance Trends: Historical data and trend analysis to identify patterns and predict future performance. By analyzing historical trends, managers can identify recurring issues and implement preventive measures to avoid them in the future.

Alerts and Notifications: Automatic alerts and notifications triggered by predefined thresholds or anomalies in equipment performance. These alerts enable managers to respond quickly to deviations from expected performance and take corrective actions as needed.

Benefits of an OEE Dashboard

An OEE dashboard offers several benefits for manufacturing companies seeking to improve operational efficiency and maximize productivity:

Real-time Visibility: Provides real-time insights into equipment performance, allowing managers to monitor operations closely and respond promptly to issues as they arise.

Data-driven Decision Making: Enables data-driven decision making by presenting key performance metrics in an easy-to-understand format. Managers can use this data to identify areas for improvement and prioritize initiatives accordingly.

Continuous Improvement: Facilitates continuous improvement by identifying opportunities to optimize equipment performance, reduce downtime, and improve product quality.

Resource Optimization: Helps optimize resource utilization by identifying bottlenecks, minimizing downtime, and maximizing equipment efficiency.

Improved Productivity: Leads to improved productivity and throughput by identifying and addressing inefficiencies in production processes.

Enhanced Quality Control: Facilitates better quality control by monitoring product quality metrics in real time and taking corrective actions to minimize defects.

Cost Savings: Ultimately, an OEE dashboard can lead to cost savings through increased efficiency, reduced downtime, and improved product quality.

Conclusion

In conclusion, an OEE dashboard is a valuable tool for manufacturing companies looking to optimize their production processes and improve operational efficiency. By providing real-time insights into equipment performance, downtime analysis, production output, and quality control metrics, an OEE dashboard empowers managers to make data-driven decisions and drive continuous improvement initiatives.

The Maurya Sir 32 week ago

https://themauryasir.com/how-to-deploy-an-avatar-soundboard-for-calling/