Domain Name System (DNS) acts like the internet’s phonebook, converting human-friendly domain names into machine-readable IP addresses so your device can reach websites and services.

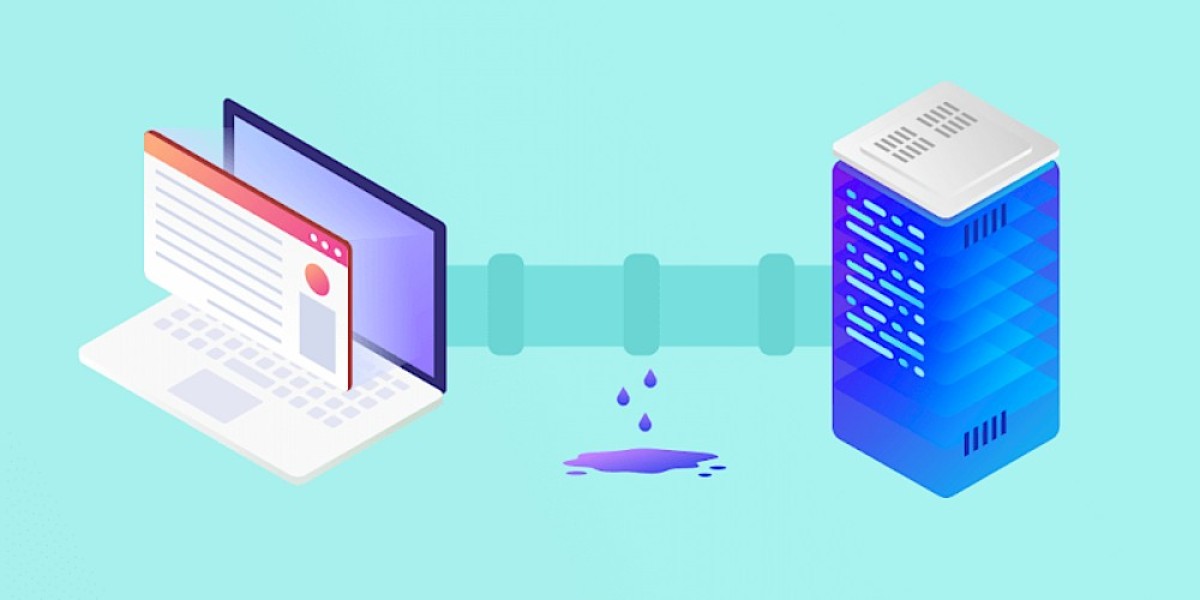

A DNS leak happens when those DNS queries escape the protections you expect—allowing your Internet Service Provider (ISP) or another third party to see which sites and services you’re contacting even if other traffic is encrypted.

Why that matters: exposed DNS queries reveal the domains you visit, approximate location tied to your IP, and timing of your activity. That information can be logged, analyzed, sold, used to throttle traffic, or abused by attackers.

Common reasons DNS leaks occur:

- VPN not configured correctly (especially manual setups).

- VPN connection drops and DNS queries fall back to the ISP’s resolver.

- Local malware or a compromised router forces DNS to an outside server.

- Using third-party DNS resolvers without encryption or without routing them through the VPN tunnel.

How to check whether you have a DNS leak:

1) Open a reputable DNS leak test site in a browser while connected to your VPN.

2) Run the test and note the DNS servers and locations it reports.

3) If the results show your ISP or any DNS provider unrelated to your VPN, you likely have a leak.

Practical steps to prevent DNS leaks:

- Use a trustworthy VPN that routes DNS queries through its encrypted tunnel or operates its own DNS servers.

- Prefer VPNs that implement a kill switch so all traffic stops if the VPN disconnects.

- Choose providers that support encrypted DNS protocols (DoH or DoT) to protect queries in transit.

- Avoid manual configuration mistakes—use official apps where possible rather than hand-setting DNS on the device.

- Secure your home router: change default credentials, update firmware, and consider running the VPN at the router level.

- Keep devices patched and scan for malware that can tamper with network settings.

A quick checklist to confirm protection:

- Connect to your VPN and run a DNS leak test.

- Verify DNS entries belong to the VPN provider, not your ISP.

- Enable the VPN kill switch and retest while simulating a disconnection if the client allows.

Choosing a provider: prioritize paid, reputable VPN services that publish independent audits, maintain a strict no-logs policy, offer device apps (reducing manual setup risks), and either operate their own DNS infrastructure or guarantee DNS routing through the VPN.

Regularly testing for leaks and using the safeguards above will keep your DNS queries private and reduce the chance your ISP or others can monitor your browsing patterns.

Why People Need VPN Services to Unblock Porn

People turn to VPN services to unblock porn primarily to bypass geographical restrictions enforced by governments or institutions and to safeguard their online privacy while accessing such content. Essentially, "porn unblocked" refers to the capability of circumventing these internet filters and censorship mechanisms to freely access adult websites that would otherwise be inaccessible or monitored. Using a VPN allows individuals to achieve this goal securely and anonymously.

Why Choose SafeShell VPN to Access Adult Content

If people want to Access region-restricted content of Porn by Porn unblock, they may want to consider SafeShell VPN. By rerouting your connection through foreign servers and hiding your real IP, SafeShell VPN makes it straightforward to unblock porn sites while keeping your browsing anonymous and shielded from ISPs or network snoops.

Beyond simple unblocking, SafeShell VPN brings a suite of protections and conveniences: modern encryption and its stealthy ShellGuard protocol keep traffic confidential and hard to detect, a large global server fleet helps you reach different regional libraries, and a fast backbone minimizes buffering so high-definition streams play smoothly. The app-level routing feature lets you direct individual apps through different country endpoints without repeatedly changing servers, and a strict no-logs approach plus a kill switch adds extra layers of safety.

For everyday use this means a balance of speed, privacy, and flexibility—protecting multiple devices at once (including desktops, phones, and streaming boxes) while giving you reliable access to content that might otherwise be blocked. If privacy-conscious streaming and the ability to unblock porn sites matter to you, SafeShell VPN is designed to make that experience both secure and simple.

How to Use SafeShell VPN to Unlock Porn Sites

Start by signing up for a plan on SafeShell VPN and creating your account, then download and install the official app on the device you’ll use for streaming. Open the app, sign in, and enable any privacy-focused features (such as App Mode or a kill switch) before selecting a server in the country whose content you want to access; once connected, confirm your virtual location with an IP check and then open your preferred adult site to stream as usual.

For smoother playback and added anonymity, clear your browser cookies or use a private window, pick a server that balances the desired country location with low latency for better speed, and switch VPN protocols if you encounter buffering or access blocks. If a site still restricts access, try a different server or contact SafeShell VPN support, keep the app updated, and always be mindful of local laws and the service’s terms when accessing region-restricted content.