Cap applicators are essential components in the packaging processes across a variety of industries. The ability to quickly and efficiently apply caps to products is critical in ensuring product safety, preventing leakage, and extending shelf life.

Industry-Specific Applications:

- Food and Beverages: The food & beverage industry is the largest end-user of cap applicators. With the growing trend of convenience foods and ready-to-drink beverages, manufacturers need high-speed capping solutions to keep up with the rapid production cycles. Cap applicators help ensure that each bottle is sealed tightly, reducing the risk of contamination or spoilage.

Hot-Fill Applications: Certain beverages require capping during hot-fill processes to preserve freshness and flavor. Cap applicators designed for this purpose must withstand high temperatures and maintain accuracy.

- Pharmaceuticals: In the pharmaceutical industry, capping systems are crucial for ensuring the integrity and safety of drug packaging. Pharmaceutical products, particularly those in liquid form, require tamper-evident caps to comply with regulatory standards. Automated cap applicators are favored for their ability to apply tamper-evident and child-resistant caps securely and efficiently.

- Cosmetics and Personal Care: As demand for cosmetic products rises, the need for reliable packaging solutions becomes more critical. The cosmetic industry often requires varied capping solutions to handle bottles of different shapes and sizes. Cap applicators designed for this sector must also account for delicate or expensive ingredients, where precision in sealing is critical.

- Chemicals and Household Products: The chemical industry uses cap applicators to seal products like cleaning solutions, detergents, and industrial chemicals. These caps often need to be designed to prevent leakage during transport, making the reliability of the applicator paramount.

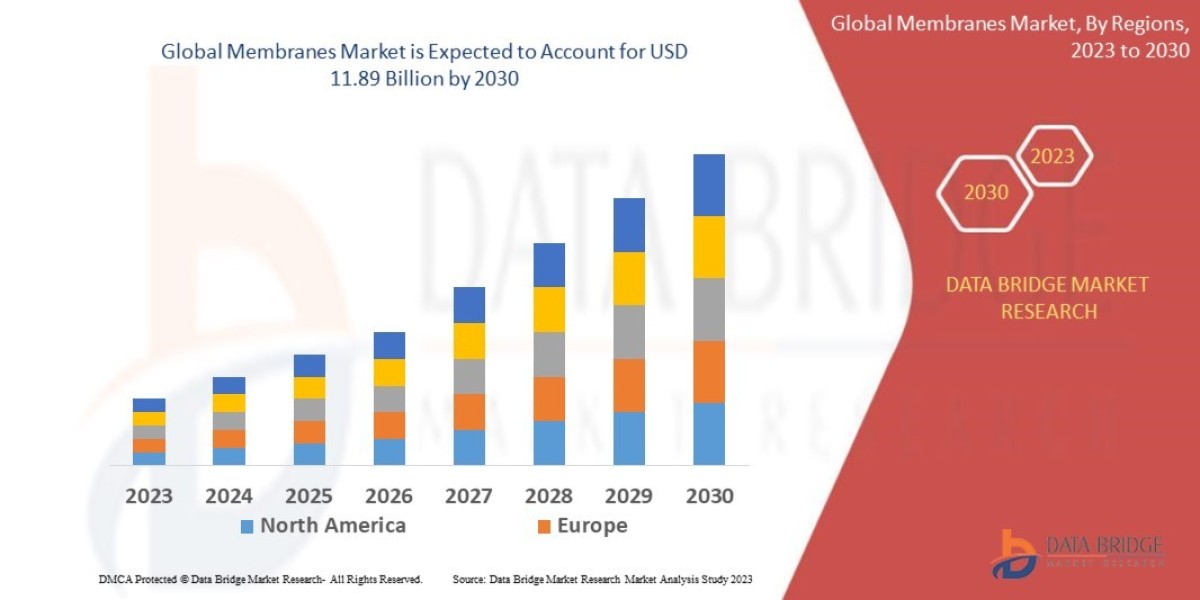

Regional Insights:

- North America remains a leading region due to high demand in the food and pharmaceutical industries and the presence of major global brands. The U.S. is a major market for advanced cap applicators due to its manufacturing capabilities and focus on high-quality packaging solutions.

- Europe has a well-established market for cap applicators, particularly in pharmaceuticals and cosmetics. The region is also seeing an increase in demand for sustainable packaging solutions, which is influencing the development of new applicators that can handle eco-friendly materials.