Modular systems have emerged as a critical solution for a variety of applications, offering customizable structures that can adapt to evolving operational needs. Whether for automation setups, display systems, or workspace layouts, these solutions provide unmatched versatility. Many companies now turn to digital platforms to discover more about available options, streamlining the process of selecting the perfect modular components for their projects.

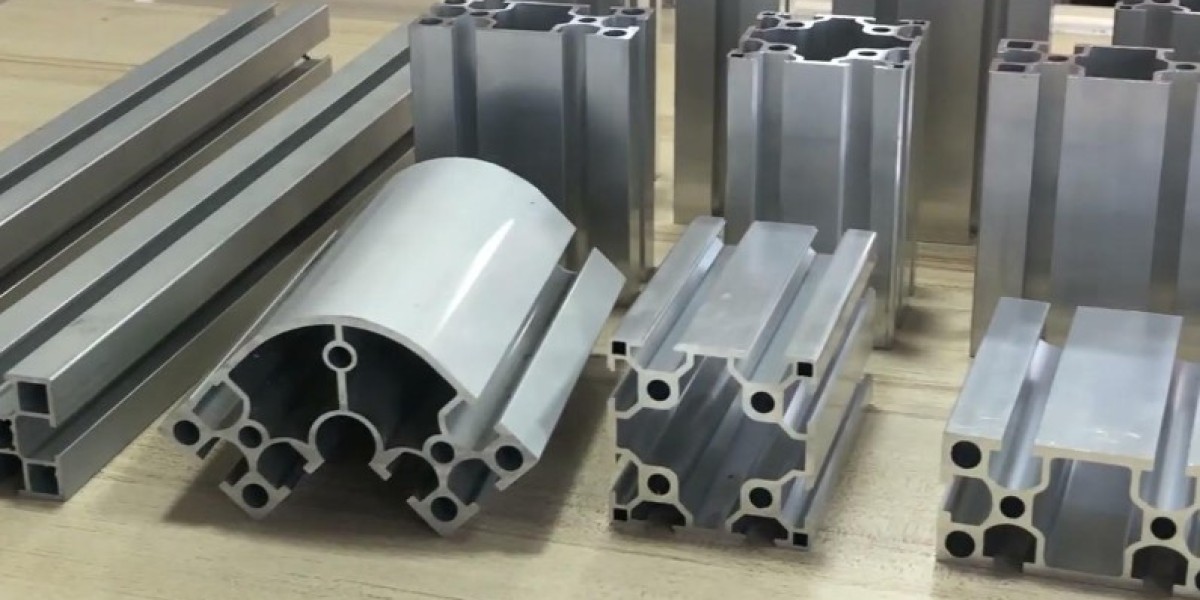

Modern modular systems are built to simplify installation, reduce assembly time, and allow seamless scalability. Components are often made from lightweight yet durable materials, such as aluminum, which combines strength with corrosion resistance. This allows businesses to invest in solutions that are both robust and adaptable to future growth.

Understanding the Advantages of Modular Systems

Flexibility and Adaptability

One of the primary advantages of modular systems is their flexibility. Unlike traditional fixed structures, modular solutions can be reconfigured as operational requirements change. Businesses can expand or modify existing setups without major structural changes, saving both time and costs.

Time and Cost Efficiency

Pre-engineered modular components significantly reduce assembly time. Companies can install or reconfigure systems quickly, which minimizes downtime and accelerates project completion. This efficiency often translates to lower overall project costs compared to traditional construction or manufacturing approaches.

Durability and Reliability

High-quality modular systems are designed to withstand demanding industrial environments. Using materials like precision-engineered aluminum ensures that the components are strong, lightweight, and resistant to wear and corrosion. This reliability makes them ideal for both indoor and outdoor applications.

Streamlined Maintenance

Modular systems are easier to maintain because individual components can be replaced or upgraded without dismantling the entire structure. This simplifies upkeep and reduces operational interruptions.

Applications Across Industries

Manufacturing and Automation

Modular frames and supports are extensively used in manufacturing plants and automated production lines. They provide structural support for machinery, workstations, and conveyor systems while allowing for easy modifications as production requirements evolve.

Retail and Exhibitions

In retail stores and trade shows, modular displays create visually appealing layouts that can be adjusted based on seasonal promotions or brand campaigns. The ability to reconfigure components ensures maximum engagement and effective use of space.

Office and Workspace Solutions

Businesses are increasingly adopting modular office systems to create flexible workspaces. Desks, partitions, and shelving units can be customized to meet the unique needs of teams, improving workflow and collaboration.

Healthcare and Educational Facilities

Hospitals, clinics, and schools benefit from modular systems for temporary or permanent setups. These include partitions, information displays, and specialized equipment stands, which can be rearranged as requirements change.

How Customization Enhances Modular Effectiveness

While standard modular components are versatile, customization unlocks their full potential. By tailoring dimensions, finishes, and configurations, businesses can create systems that perfectly align with operational needs and aesthetic goals. Companies can discover more about custom options, including frame sizes, panel types, and accessories, ensuring that each solution fits seamlessly into the intended environment.

Custom modular solutions also allow for the integration of technology, such as built-in lighting, cable management, or interactive elements, enhancing both functionality and visual appeal.

Importance of Selecting a Reliable Supplier

The effectiveness of modular systems depends heavily on the quality and precision of the components. Partnering with a trusted supplier ensures that the materials, engineering, and manufacturing processes meet high standards. A reliable supplier provides:

High-precision manufacturing of aluminum frames and components

Comprehensive catalog options for varied applications

Guidance on design and assembly

Timely delivery and support for installation

Working with an experienced provider reduces the risk of delays, errors, and substandard performance, ensuring that modular systems perform reliably in real-world applications.

Classic Modul: Expertise in Modular Solutions

Classic Modul stands out as a leading provider of advanced modular systems. Their catalog offers a wide selection of pre-engineered and customizable solutions, designed to meet the needs of industrial, commercial, and architectural projects. By combining precision aluminum engineering with innovative design, Classic Modul ensures components that are durable, lightweight, and versatile.

Clients can discover more about available solutions by exploring the catalog, allowing them to select components that match their specific project requirements. The company’s commitment to quality, customization, and customer support makes them a preferred partner for businesses seeking reliable modular systems.

Future Trends in Modular Systems

The modular solutions industry continues to evolve with technological and material innovations. Some emerging trends include:

Increased use of lightweight, high-strength alloys for structural efficiency

Integration of smart systems for automation and interactivity

Sustainable materials and energy-efficient manufacturing processes

Modular designs that allow for rapid assembly and disassembly

These trends reflect a growing demand for solutions that are both environmentally responsible and highly adaptable to changing industrial and commercial needs.

Sustainability and Environmental Responsibility

Sustainable design is increasingly important in modular manufacturing. Aluminum is highly recyclable without losing structural integrity, reducing environmental impact. Manufacturers focused on sustainability use energy-efficient production processes, minimize material waste, and offer components that can be reused or upgraded over time.

Investing in modular systems designed with sustainability in mind allows businesses to achieve operational efficiency while supporting environmental responsibility.

Conclusion

Modular systems have transformed the way businesses approach workspace design, industrial setups, and display solutions. Their flexibility, durability, and ease of customization make them essential for companies seeking scalable and efficient solutions. Businesses can discover more about available options and select solutions that meet both functional and aesthetic requirements.

Partnering with a trusted provider like Classic Modul ensures access to high-quality aluminum components, precise engineering, and comprehensive support throughout the design and implementation process. By leveraging modular solutions, businesses can enhance productivity, improve space utilization, and maintain adaptability for future growth, all while creating professional and visually appealing environments.