A diesel engine pump factory plays a significant role in supplying equipment that supports a variety of industrial and agricultural operations. Diesel engine pumps are valued for their ability to deliver stable flow and pressure in environments where electric power is limited or unreliable. These pumps are frequently used in irrigation, construction, mining, and emergency water transfer. The factory environment where these pumps are produced requires a combination of engineering knowledge, material expertise, and precision assembly.

Manufacturing begins with the selection of components suited for continuous operation. The engine block, pump body, impellers, and fuel system parts are prepared using metals capable of handling heat, vibration, and long-term mechanical stress. Machining teams shape these components through processes such as turning, milling, drilling, and casting. Each step ensures the parts have accurate dimensions and smooth surfaces, which contribute to consistent hydraulic performance.

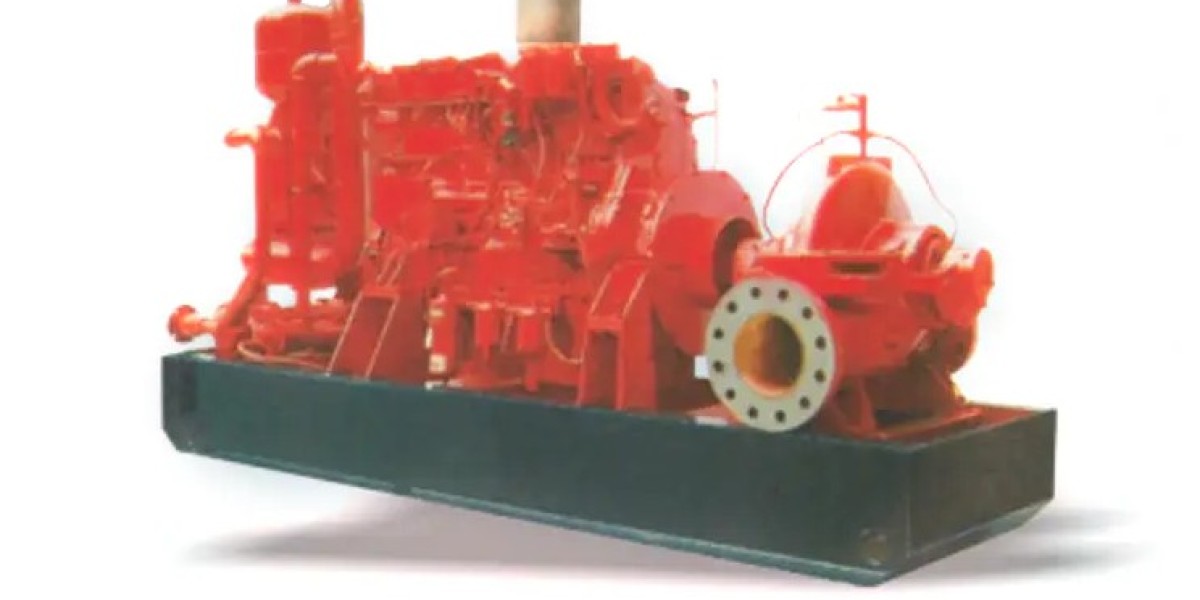

After machining, technicians in the diesel engine pump factory move to the assembly phase. The engine and pump sections must be connected carefully to guarantee proper alignment. A misaligned shaft or an inaccurately positioned impeller can reduce efficiency and increase wear. Bearings, seals, fuel injectors, and cooling parts are installed, and the final structure is reinforced to withstand outdoor or heavy-duty environments.

Testing is an essential part of production. Every diesel engine pump undergoes inspections to confirm flow rate, discharge pressure, fuel consumption, and noise levels. The factory typically conducts both cold and hot tests, allowing technicians to observe the unit under different operating conditions. Any irregularities are corrected before release.

Modern diesel engine pump factories also focus on research and improvement. Engineers study engine combustion efficiency, pump hydraulic design, and material durability to reduce maintenance frequency and enhance operational stability. Many facilities adopt digital monitoring tools that record performance data during testing, helping adjust future designs and production methods.

Safety and environmental guidelines shape daily activities within the factory. Workers follow established handling procedures for fuels, lubricants, and metal waste. Ventilation, protective equipment, and quality checks help ensure that manufacturing maintains consistent standards without compromising worker safety.

Overall, a diesel engine pump factory supports critical industrial systems by providing durable and reliable pumping solutions. Their work ensures that industries requiring continuous water movement or fuel-powered operation can function with dependable mechanical support.