Industrial Lubricants Market: Navigating Through Growth and Innovation

In the realm of industrial operations, the efficacy of machinery and equipment is paramount. The smooth functioning of heavy machinery in manufacturing units, construction sites, and various other industrial settings hinges upon a crucial element: lubrication. Industrial lubricants play a pivotal role in ensuring the seamless operation of machinery, reducing friction, preventing wear and tear, and ultimately prolonging the lifespan of equipment. The Industrial Lubricants Market, driven by technological advancements and evolving industrial landscapes, is witnessing robust growth and innovation. In this comprehensive market analysis, we delve into the dynamics, trends, and factors shaping the Industrial Lubricants Market landscape.

Understanding the Industrial Lubricants Market Landscape

An Overview of the Market

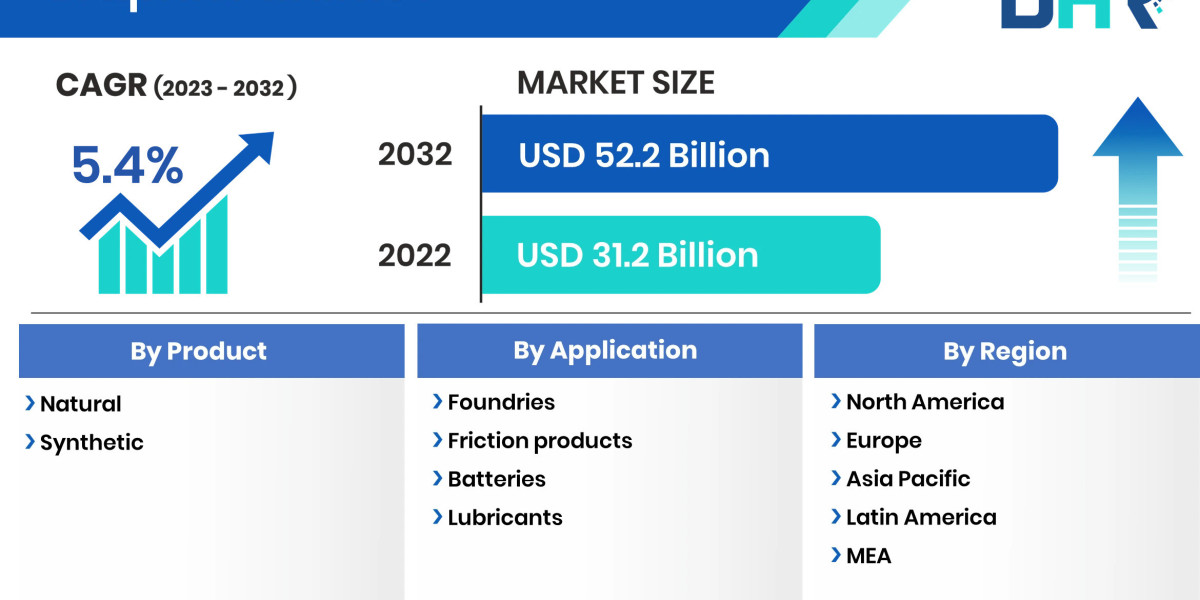

The Global Industrial Lubricants Market is on an upward trajectory, poised to achieve a significant valuation of USD 60,955.2 million by 2024. Projections indicate a robust Compound Annual Growth Rate (CAGR) of 4.5% for the forecast period spanning 2024 to 2033. This growth is fueled by a confluence of factors, including the increasing industrialization, burgeoning manufacturing activities, and the imperative need for enhanced machinery performance and longevity.

Key Takeaways

- Technological advancements drive innovation and growth in the Industrial Lubricants Market.

- Diverse end-user industries, including automotive, construction, and oil & gas, fuel market demand.

- Synthetic and bio-based lubricants offer superior performance and environmental sustainability.

- Strategic collaborations and partnerships are key strategies for market players to expand their reach.

- Compliance with regulatory standards and certifications is essential for lubricant manufacturers.

- Emphasis on energy efficiency and predictive maintenance propels market evolution.

- Additive technology integration and digitalization are shaping future trends in the industry.

Get a Free PDF Sample Copy of This Report@ https://dimensionmarketresearch.com/report/industrial-lubricants-market/request-sample

Key Factors

- Technological Advancements

- Increasing Industrialization

- Focus on Equipment Maintenance

- Stringent Regulatory Standards

- Expansion of End-Use Industries

- Emphasis on Energy Efficiency

- Strategic Collaborations and Partnerships

- Emerging Trends in Additive Technology

Targeted Audience

- Industrial Lubricant Manufacturers

- Machinery and Equipment Suppliers

- End-User Industries (Automotive, Construction, Oil & Gas, etc.)

- Regulatory Authorities and Compliance Agencies

- Research and Development Organizations

- Investors and Stakeholders

- Consulting Firms and Market Analysts

- Academic Institutions and Students

Segmentation Analysis

The Industrial Lubricants Market is segmented based on various parameters, offering insights into diverse facets of lubricant usage across industries.

By Base Oil

- Synthetic Oil: Engineered for superior performance, synthetic oils offer enhanced lubrication properties, thermal stability, and resistance to oxidation, catering to high-demand industrial applications.

- Mineral Oil: Traditional yet reliable, mineral oils serve as a cost-effective lubrication solution, suitable for a wide array of industrial machinery and equipment.

- Bio-Based Oil: With a focus on sustainability, bio-based oils are gaining traction, offering environmentally friendly lubrication options without compromising on performance.

By Product

- Hydraulic Fluid: Vital for hydraulic systems, hydraulic fluids facilitate energy transmission, lubrication, and heat dissipation, ensuring optimal performance and safety.

- Gear Oil: Engineered to withstand heavy loads and extreme conditions, gear oils provide crucial lubrication to gears, reducing friction and minimizing wear.

- Grease: Versatile and durable, grease finds applications in bearings, joints, and other moving parts, offering long-lasting lubrication and protection against contaminants.

- Metal Working Fluid: Essential for metalworking processes, metalworking fluids aid in cooling, lubrication, and chip removal, optimizing machining operations.

- Turbine Oil: Designed for use in turbines and compressors, turbine oils offer exceptional oxidation stability, thermal resistance, and anti-foaming properties, ensuring reliable performance.

- Transformer Oil: Critical for electrical transformers, transformer oils provide insulation, cooling, and arc suppression, safeguarding equipment and ensuring efficient power transmission.

- Others: This category encompasses a diverse range of specialty lubricants tailored to specific industrial applications, including heat transfer fluids, pneumatic oils, and refrigeration oils.

By End-User

- Metal & Mining: From heavy-duty mining equipment to metal processing machinery, the metal and mining sector relies on industrial lubricants to optimize operational efficiency and mitigate downtime.

- Construction: Construction machinery and equipment operate in challenging environments, necessitating robust lubrication solutions to withstand rugged conditions and ensure productivity.

- Power Generation: In power plants and utilities, industrial lubricants play a critical role in maintaining the reliability and performance of turbines, generators, and other power generation equipment.

- Cement Production: Cement manufacturing involves high-temperature processes and heavy machinery, underscoring the importance of specialized lubricants to sustain operations and minimize maintenance.

- Oil & Gas: From drilling rigs to refining operations, the oil and gas industry relies on industrial lubricants to optimize equipment performance, mitigate corrosion, and enhance safety.

- Textile: Textile manufacturing machinery demands precise lubrication to support continuous operation and prevent downtime, ensuring seamless production processes.

- Food Processing: Hygiene and food safety are paramount in food processing facilities, driving the demand for food-grade lubricants that meet stringent regulatory standards while delivering effective lubrication.

- Automotive: From automotive manufacturing to aftermarket maintenance, industrial lubricants are indispensable for ensuring the smooth operation of engines, transmissions, and other automotive components.

- Others: This category encompasses a diverse range of industries and applications, including aerospace, marine, pharmaceuticals, and more, each requiring tailored lubrication solutions to meet specific operational needs.

Buy This Report Here@ https://dimensionmarketresearch.com/checkout/industrial-lubricants-market

Prominent Players in the Market

The Industrial Lubricants Market boasts a robust ecosystem comprising various key players driving innovation and competition.

- Fuchs Lubricants

- ExxonMobil Corp.

- Phillips 66

- The Lubrizol Corp.

- Royal Dutch Shell

- Amsoil Inc.

- Bel-Ray Co. Inc.

- Clariant

- Chevron Corp.

- TOTAL S.A

- Castrol

- Kluber Lubrication

- Other Key Players

Factors Driving Market Growth

Technological Advancements

Rapid advancements in lubricant technology, including the development of synthetic and bio-based lubricants, are driving market growth. These innovations offer superior performance, extended equipment life, and enhanced environmental sustainability, aligning with evolving industry needs and regulations.

Increasing Industrialization

The global shift towards industrialization, particularly in emerging economies, is fueling the demand for industrial lubricants. Growing manufacturing activities across sectors such as automotive, construction, and aerospace are driving the adoption of lubrication solutions to optimize operational efficiency and reduce maintenance costs.

Focus on Equipment Maintenance

Efficient equipment maintenance is a priority for industries seeking to maximize productivity and minimize downtime. Industrial lubricants play a crucial role in preventive maintenance strategies, lubricating moving parts, reducing friction, and preventing premature wear and failure, thereby enhancing equipment reliability and longevity.

Stringent Regulatory Standards

Stringent regulations governing environmental protection and workplace safety are driving the adoption of eco-friendly and specialty lubricants. Manufacturers are increasingly seeking lubrication solutions that comply with regulatory requirements while delivering optimal performance, contributing to market growth and innovation.

Expansion of End-Use Industries

The expansion of end-use industries such as automotive, construction, and oil & gas is creating lucrative opportunities for lubricant manufacturers. Rising investments in infrastructure development, coupled with increasing automotive production and sales, are driving the demand for high-performance lubrication solutions across diverse applications.

Emphasis on Energy Efficiency

In an era of sustainability and energy conservation, industries are prioritizing energy-efficient solutions to reduce operating costs and environmental impact. Advanced lubricants with superior lubricity, viscosity control, and thermal stability contribute to energy savings by minimizing frictional losses and improving equipment efficiency.

Strategic Collaborations and Partnerships

Key players in the industrial lubricants market are engaging in strategic collaborations and partnerships to expand their product portfolios and geographical reach. Joint ventures, acquisitions, and alliances enable companies to leverage complementary strengths and resources, accelerate innovation, and capture new market opportunities.

Emerging Trends in Additive Technology

The integration of advanced additive technologies is emerging as a key trend in the industrial lubricants market. Additives such

as friction modifiers, antioxidants, and anti-wear agents enhance lubricant performance, prolong equipment life, and address specific application challenges, driving market growth and differentiation.

Recent Development

• March 2024, ExxonMobil will invest nearly USD 110 million in a Maharashtra plant, producing 159,000 kiloliters of lubricants annually, targeting commercial startups by late 2025, which aims to support local sourcing by new job opportunities.

• October 2022, Valeo and Totalenergies formed an agreement to develop a new product that can minimize the heat emissions by batteries in electric vehicles by using high-performance dielectric liquid.

• July 2022, SKF RecondOil’s Double Separation Technology (DST) with Quaker Houghton’s industrial oils has come into agreement to share their expertise in this market by working together to reduce the unsustainable use of oil.

• January 2022, Chevron Corporation a subsidiary of Chevron Lubricants Lanka PLC formed a marketing agreement with Rock Energy in Bangladesh for their lubricant product and market expansion.

Frequently Asked Questions (FAQs)

1. What are the key factors driving the growth of the Industrial Lubricants Market?

The growth of the Industrial Lubricants Market is propelled by factors such as technological advancements, increasing industrialization, focus on equipment maintenance, stringent regulatory standards, expansion of end-use industries, emphasis on energy efficiency, strategic collaborations, and emerging trends in additive technology.

2. What are the major segments of the Industrial Lubricants Market?

The Industrial Lubricants Market is segmented based on base oil (synthetic oil, mineral oil, bio-based oil), product type (hydraulic fluid, gear oil, grease, metal working fluid, turbine oil, transformer oil, others), and end-user industry (metal & mining, construction, power generation, cement production, oil & gas, textile, food processing, automotive, others).

3. How do synthetic lubricants differ from mineral oils?

Synthetic lubricants are chemically engineered to offer superior performance characteristics such as higher viscosity index, thermal stability, oxidation resistance, and extended drain intervals compared to mineral oils. They are ideal for high-demand industrial applications requiring enhanced lubrication properties and durability.

4. What are the regulatory considerations for industrial lubricants?

Industrial lubricants are subject to various regulatory standards governing environmental protection, workplace safety, and product quality. Manufacturers must ensure compliance with regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and NSF (National Sanitation Foundation) certifications for food-grade lubricants.

5. How do industrial lubricants contribute to equipment maintenance?

Industrial lubricants play a critical role in equipment maintenance by lubricating moving parts, reducing friction, preventing wear and corrosion, dissipating heat, and sealing out contaminants. Proper lubrication extends equipment life, improves operational efficiency, and minimizes downtime and maintenance costs.

6. What are the emerging trends in the Industrial Lubricants Market?

Emerging trends in the Industrial Lubricants Market include the adoption of bio-based and environmentally friendly lubricants, advancements in additive technology, digitization of lubricant management systems, and the rise of predictive maintenance solutions leveraging IoT (Internet of Things) and AI (Artificial Intelligence) technologies.

Conclusion

In conclusion, the Industrial Lubricants Market is characterized by robust growth, driven by technological advancements, increasing industrialization, and evolving end-user requirements. Key players in the market are focusing on innovation, sustainability, and strategic partnerships to capitalize on emerging opportunities and stay competitive in the dynamic landscape. As industries continue to prioritize equipment reliability, efficiency, and compliance with regulatory standards, the demand for advanced lubrication solutions is expected to witness sustained growth, shaping the future of industrial operations globally.

About Us

Dimension Market Research (DMR) is the ultimate one step solution to all your research needs and requirements. Dimension Market Research is India and US based company, we have headquarter in USA (New York) with offices in Asia pacific region. Dimension Market Research is specifically designed to provide most relevant syndicated, customized and tailor made market research to suit your specific business needs.