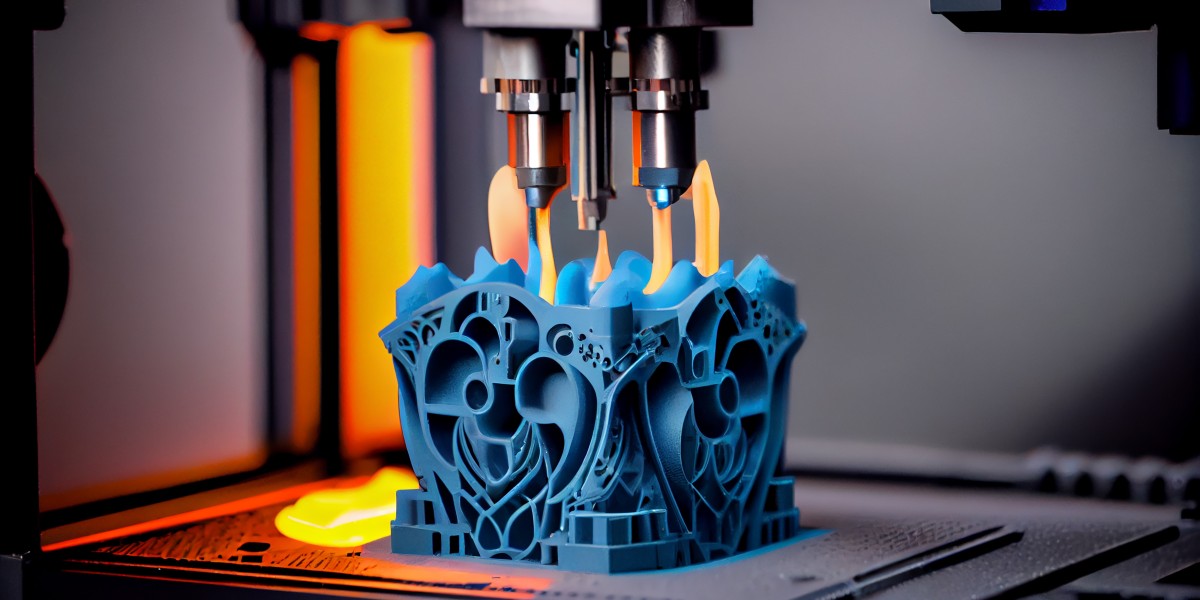

In today’s fast-paced world of additive manufacturing, micro 3D printing is revolutionizing industries that require extreme precision, intricate detail, and high-performance materials. From medical devices to electronics, the demand for accurate miniature components is growing rapidly. Choosing the right materials is essential to achieving the desired balance of precision, durability, and strength. In this article, we’ll explore some of the most popular micro 3D printing materials and their applications, with insights from Tesseract 3D.

What Is Micro 3D Printing?

Micro 3D printing is a specialized form of additive manufacturing that focuses on creating parts at a micron or sub-millimeter scale. Unlike conventional 3D printing, micro-scale printing technologies—such as two-photon polymerization (TPP), micro-stereolithography (µSLA), and micro-extrusion—enable the production of intricate geometries with extremely fine details.

Key Considerations for Choosing Micro 3D Printing Materials

When selecting materials for micro 3D printing, the following factors are crucial:

- Dimensional Accuracy: Materials must allow for fine resolutions without warping.

- Strength and Durability: Components should withstand mechanical stress where required.

- Biocompatibility: Essential for medical or dental applications.

- Thermal and Electrical Properties: Important for electronics and aerospace.

Tesseract 3D emphasizes matching materials not just to the printing process, but also to the specific end-use application.

Popular Materials for Micro 3D Printing

1. Photopolymer Resins

Resins are widely used in micro 3D printing because of their high resolution and smooth surface finish. Specialized formulations allow for varying degrees of strength, flexibility, or transparency. These materials are ideal for prototypes, microfluidic devices, and optical components.

2. Metals

Metal micro 3D printing is gaining traction in industries requiring strength and conductivity. Materials like stainless steel, titanium, and copper are used to manufacture micro-electronic connectors, medical implants, and aerospace components. While more complex to process, metal micro-printing offers unparalleled durability.

3. Ceramics

Ceramic-based materials provide excellent heat resistance and hardness, making them suitable for micro-scale aerospace or automotive parts. They are also used in dental and biomedical fields due to their biocompatibility.

4. Polymers and Composites

High-performance polymers such as PEEK (Polyether ether ketone) are used when mechanical strength and chemical resistance are required. Composite materials further enhance functionality by combining polymer bases with fibers or nanoparticles.

Applications of Micro 3D Printing Materials

- Medical Devices: Stents, micro-needles, and surgical instruments.

- Electronics: Micro-sensors, antennas, and connectors.

- Aerospace Defense: Lightweight structural parts and miniature components.

- Optics: Lenses and microfluidic chips.

By leveraging advanced materials, Tesseract 3D helps businesses push the boundaries of what is possible in precision engineering.

Conclusion

Micro 3D printing is opening new possibilities across industries by combining unmatched accuracy with strong, versatile materials. From resins to metals and ceramics, the choice of material plays a defining role in achieving both precision and performance. Partnering with experts like Tesseract 3D ensures that businesses not only select the right materials but also unlock the full potential of micro 3D printing technology.