Aliphatic Polyester Polyols Market: Trends, Forecast, and Growth Prospects (2024-2034)

The Aliphatic Polyester Polyols market is predicted to develop at a compound annual growth rate (CAGR) of 6.3% from 2024 to 2034, when it is projected to reach USD 6,632.85 Million in 2034, based on an average growth pattern. The market is estimated to reach a value of USD 2,576.38 Million in 2024.

Request Sample PDF Copy : https://wemarketresearch.com/reports/request-free-sample-pdf/aliphatic-polyester-polyols-market/1555

What Are Aliphatic Polyester Polyols?

Aliphatic Polyester Polyols are a type of polyol used primarily in the production of polyurethanes, which are widely used in coatings, adhesives, foams, elastomers, and thermoplastic polyurethane (TPU) materials. These polyols are synthesized from aliphatic acids or lactones and are known for their superior chemical resistance, low toxicity, and high performance. They are key ingredients in manufacturing high-quality, durable products in various end-use industries.

Key Drivers of Aliphatic Polyester Polyols Market Growth

- Increasing Demand for Polyurethane-based Products Aliphatic Polyester Polyols are a key raw material in the production of polyurethanes, which have a broad range of applications in industries such as construction, automotive, and textiles. The growing demand for polyurethane coatings, adhesives, and foams is a significant factor driving the market growth of Aliphatic Polyester Polyols.

- Growing Automotive and Construction Sectors In the automotive sector, Aliphatic Polyester Polyols are used in the production of high-performance coatings, seat cushioning, and insulation materials. Similarly, in construction, polyurethane-based materials are in high demand for insulation, flooring, and coatings. As both sectors expand globally, the demand for Aliphatic Polyester Polyols is expected to rise accordingly.

- Sustainability and Eco-friendly Products With increasing environmental concerns, industries are turning toward sustainable and eco-friendly materials. Aliphatic Polyester Polyols are considered more environmentally friendly compared to other polyols due to their lower toxicity and reduced impact on the environment. This shift toward greener alternatives is expected to bolster market growth.

- Rising Demand for High-performance Materials The versatility and superior properties of polyurethane products made from Aliphatic Polyester Polyols, such as enhanced chemical resistance, flexibility, and durability, are driving their adoption in a wide range of applications, including synthetic leather, footwear, and electronics.

Market Segmentation

The Aliphatic Polyester Polyols market is segmented based on type, application, end-use industry, and region. Let’s take a closer look at each segment:

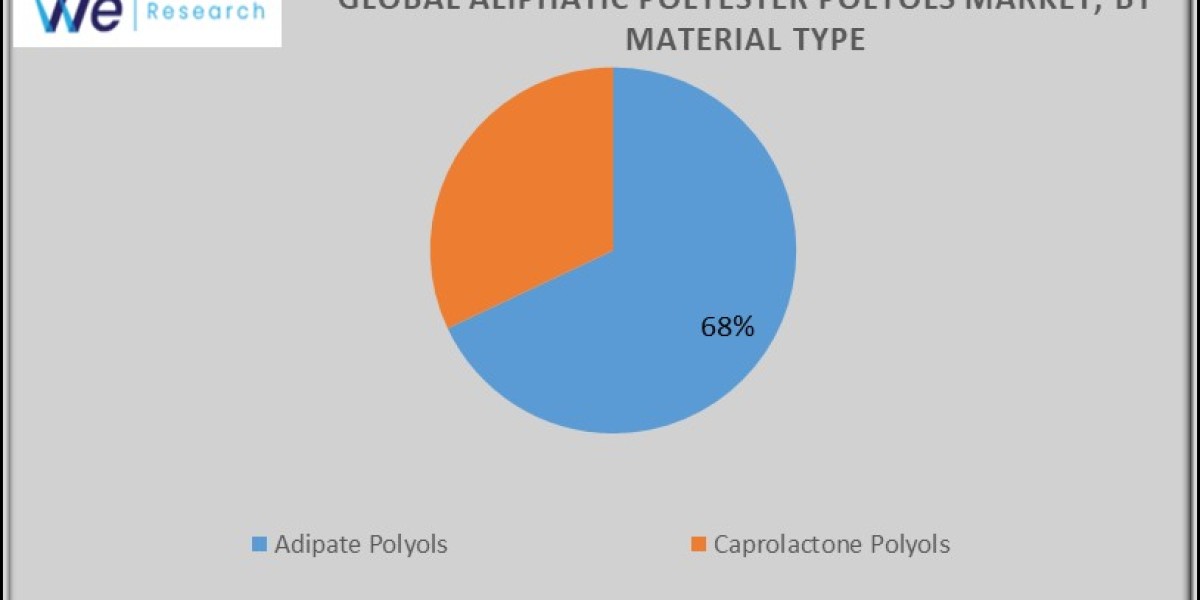

By Type:

- Adipate Polyols: Adipate Polyols are a widely used type of aliphatic polyester polyol. These polyols offer excellent low-temperature flexibility and hydrolytic stability, making them suitable for a wide range of polyurethane applications. The demand for adipate polyols is expected to grow as more industries seek to produce durable and weather-resistant products.

- Caprolactone Polyols: Caprolactone Polyols are used in the production of high-performance polyurethane products, particularly in applications where high chemical resistance and flexibility are needed. These polyols are gaining popularity in specialty applications, driving growth in this segment.

By Application:

- Polyurethane Coatings: Aliphatic Polyester Polyols are used in the production of high-quality polyurethane coatings, which are essential in automotive, construction, and industrial applications. These coatings offer durability, chemical resistance, and a glossy finish, driving demand in the market.

- Polyurethane Adhesives: The demand for Aliphatic Polyester Polyols in adhesives is growing, particularly in the automotive and construction sectors. Polyurethane adhesives made from these polyols are strong, flexible, and durable, making them ideal for bonding various materials.

- Polyurethane Elastomers: Aliphatic Polyester Polyols are used to produce polyurethane elastomers, which are vital in the manufacturing of wear-resistant parts, wheels, and seals. These elastomers are known for their superior mechanical properties, including abrasion resistance and toughness.

- Polyurethane Foams: Flexible and rigid polyurethane foams made from Aliphatic Polyester Polyols are widely used in the automotive and furniture industries for insulation, cushioning, and packaging. The growing need for energy-efficient and lightweight materials is driving the demand for these foams.

By End-use:

- Construction: In the construction sector, polyurethane-based materials made from Aliphatic Polyester Polyols are used for insulation, flooring, and coatings. The growing construction industry, particularly in emerging markets, is a major driver of demand for these materials.

- Automotive: The automotive industry uses polyurethane materials for seat cushioning, insulation, and coatings. Aliphatic Polyester Polyols are crucial in producing durable and high-performance automotive components.

- Textiles: Polyurethane fibers and coatings made from Aliphatic Polyester Polyols are used in textiles for their flexibility and resistance to abrasion. The rising demand for performance fabrics and coatings in the fashion and sportswear industries is supporting market growth.

- Packaging: Polyurethane-based materials, including foams and coatings made from Aliphatic Polyester Polyols, are used in packaging for cushioning and protective purposes. The growth of e-commerce and the demand for sustainable packaging are expected to boost the market.

Regional Insights

The Aliphatic Polyester Polyols market is growing rapidly across several regions, with key markets including:

- North America: The North American market is expected to dominate the Aliphatic Polyester Polyols industry, driven by strong demand from the automotive, construction, and packaging sectors.

- Europe: The European market is also growing, with significant demand for sustainable materials in the automotive and construction industries. Germany, France, and Italy are key contributors to market growth.

- Asia-Pacific: The Asia-Pacific region is experiencing rapid industrialization, particularly in countries like China and India, where the demand for polyurethane-based materials in construction, automotive, and textiles is on the rise.

- Latin America: The Latin American market is expanding, with increasing demand for high-performance materials in construction, automotive, and furniture applications.

- Middle East & Africa: As the construction and automotive sectors continue to grow in the Middle East, the demand for Aliphatic Polyester Polyols is expected to increase in this region as well.

Conclusion

The Aliphatic Polyester Polyols market is poised for substantial growth in the coming years. As industries increasingly rely on high-performance materials for a wide range of applications, the demand for these polyols will continue to rise. Companies operating in the Aliphatic Polyester Polyols market must capitalize on the growing demand across various end-use industries and leverage the opportunity to develop innovative and sustainable solutions.