In the realm of drilling operations, efficiency and precision are paramount. Bentonite desanders have emerged as a game-changer, offering unparalleled effectiveness in separating solids from liquids during drilling processes. These innovative devices utilize the unique properties of bentonite, a versatile clay mineral known for its exceptional absorption and adsorption capabilities.

Bentonite desanders, also known as hydrocyclones or cyclonic separators, play a crucial role in various industries, including oil and gas exploration, mining, construction, and environmental remediation. Their primary function is to remove sand, silt, and other solid particles from drilling fluids or wastewater, ensuring smooth and uninterrupted operations while minimizing environmental impact.

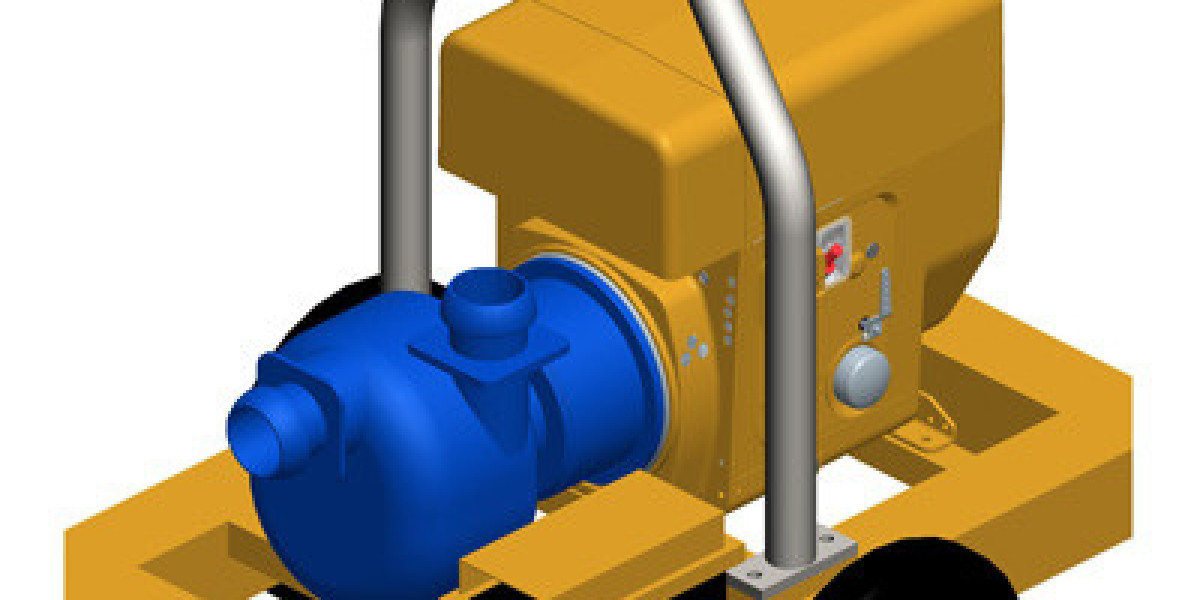

At the heart of a bentonite desander lies the hydrocyclone, a cone-shaped separator that harnesses centrifugal force to separate solids from liquids. As drilling fluids enter the desander, they are directed into the hydrocyclone, where the high rotational velocity causes the heavier solids to be forced outward and downward, while the lighter liquid phase moves upward through the center of the cone. This efficient separation process results in clean, reusable drilling fluids and significantly reduces the need for costly disposal of waste materials.

One of the key advantages of bentonite desanders is their versatility and adaptability to different drilling conditions and fluid types. Whether operating in shallow or deep wells, onshore or offshore, these systems can be customized to meet specific requirements, delivering consistent performance across a wide range of applications. Additionally, bentonite desanders can be integrated seamlessly into existing drilling rigs or used as standalone units, providing flexibility and convenience to operators.

Another benefit of bentonite desanders is their ability to enhance drilling efficiency and productivity. By removing abrasive solids from drilling fluids, these systems help prevent equipment wear and damage, reducing downtime and maintenance costs. Moreover, clean drilling fluids result in improved hole stability, better borehole conditions, and enhanced overall drilling performance, ultimately leading to faster completion times and increased project profitability.

In addition to their role in drilling operations, bentonite desanders also play a vital role in environmental protection and compliance. By effectively separating solids from wastewater, these systems help mitigate the environmental impact of drilling activities, preventing soil and water contamination and ensuring regulatory compliance. This proactive approach to environmental stewardship underscores the importance of incorporating advanced filtration technologies into modern drilling practices.

Furthermore, bentonite desanders contribute to resource conservation by promoting the reuse and recycling of drilling fluids. By recovering valuable fluids and minimizing waste generation, these systems help reduce water consumption and disposal costs, aligning with sustainable development goals and corporate responsibility initiatives.

In conclusion, bentonite desanders represent a significant advancement in drilling technology, offering unparalleled efficiency, versatility, and environmental benefits. As the demand for efficient and sustainable drilling solutions continues to grow, these innovative systems are poised to play a central role in shaping the future of the industry. With their ability to improve operational performance, protect the environment, and conserve resources, bentonite desanders are indeed a cornerstone of modern drilling operations.