In today’s fast-evolving world, sustainability has become a key focus for industries worldwide. From manufacturing to consumer products, companies are exploring innovative ways to reduce waste and create environmentally responsible solutions. One powerful tool driving this change is 3D product design. At Tesseract 3D, we believe that advanced design technologies can help build a more sustainable and eco-friendly future.

What Is 3D Product Design?

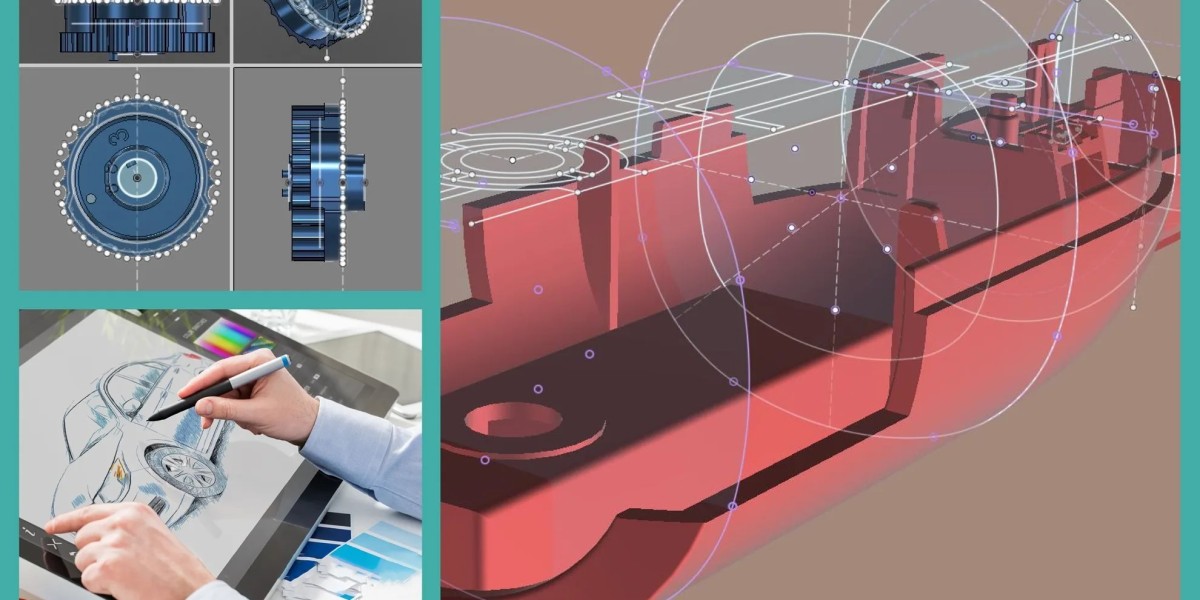

3D product design is the process of creating detailed digital models of products using specialized CAD software. This allows designers and engineers to visualize, modify, and test products before they are physically manufactured. Unlike traditional design methods, 3D modeling enables precision, flexibility, and faster prototyping — all of which are essential for sustainable development.

Reducing Material Waste

One of the biggest advantages of 3D product design is its ability to minimize material waste. Traditional manufacturing often involves trial-and-error prototyping, which consumes large amounts of resources. With 3D digital modeling, designers can test and refine every detail virtually, eliminating the need for multiple physical prototypes.

At Tesseract 3D, our design experts optimize each model to ensure efficient material use, helping businesses reduce both costs and environmental impact.

Promoting Energy Efficiency

Sustainable design isn’t only about using fewer materials—it’s also about conserving energy. Through 3D product design, engineers can simulate performance and identify energy-saving improvements before production begins. Whether it’s a lightweight structure or a more aerodynamic shape, small design tweaks can lead to significant energy savings in manufacturing and usage.

Encouraging Recyclable and Eco-Friendly Materials

Modern 3D product design allows designers to experiment with eco-friendly materials such as bioplastics, recycled polymers, and sustainable composites. By integrating these materials into the design process, manufacturers can reduce their reliance on non-renewable resources.

Tesseract 3D supports clients in selecting sustainable materials that meet both performance and environmental standards.

Accelerating the Product Lifecycle

The ability to visualize and test a product virtually shortens the development cycle dramatically. Faster design iterations mean quicker market launches and fewer production errors. Moreover, 3D product design supports circular economy principles by enabling easy redesign and reuse of digital models for future products.

Driving Innovation Through Digital Transformation

Sustainability and innovation go hand in hand. The use of 3D product design encourages companies to rethink traditional methods and adopt digital-first approaches. By implementing technologies like 3D printing and virtual simulation, businesses can achieve greater efficiency while aligning with global sustainability goals.

At Tesseract 3D, we help companies embrace digital transformation to stay competitive and eco-conscious.

Conclusion

As industries move toward greener practices, 3D product design stands out as a critical enabler of sustainable innovation. It reduces waste, saves energy, promotes recyclable materials, and accelerates product development—all while maintaining high quality and performance.

Partner with Tesseract 3D to create smart, sustainable designs that make a real difference in today’s environmentally aware market.