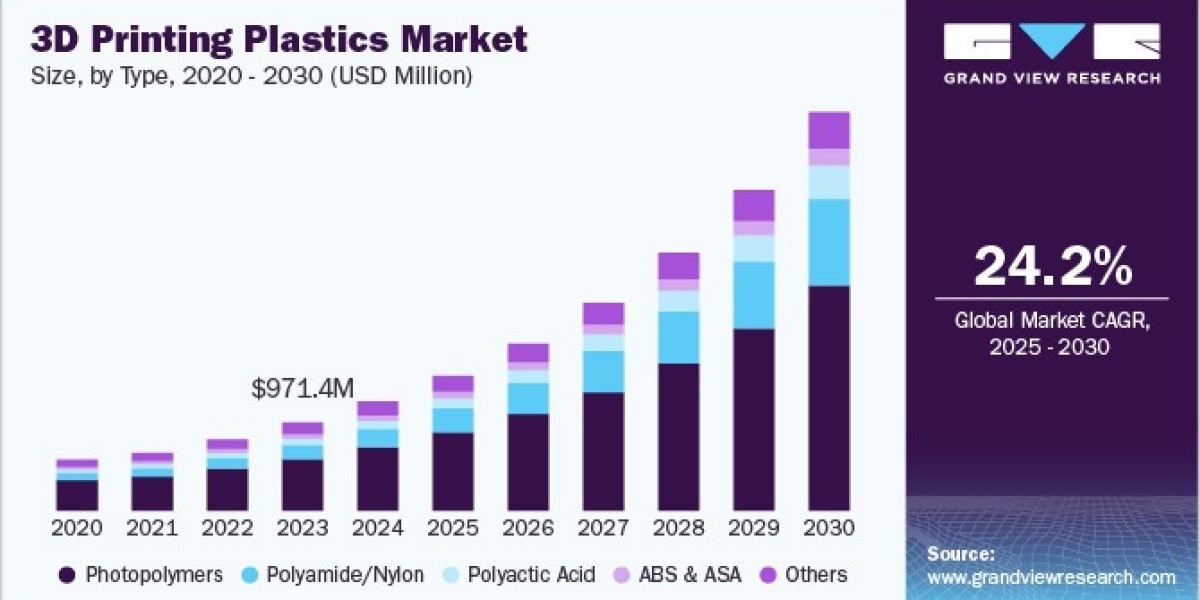

The global 3D printing plastics market, valued at USD 1.20 billion in 2024, is anticipated to experience robust growth, projected to achieve a compound annual growth rate (CAGR) of 24.2% from 2025 to 2030. This remarkable expansion is primarily driven by the increasing demand for customized and personalized products, which is fostering innovation within the 3D printing industry. As consumers and businesses alike seek tailored solutions that meet their specific needs, the necessity for versatile and high-quality 3D printing plastics is becoming increasingly prominent.

A notable trend within this market is the strong shift toward sustainable and eco-friendly materials. As various industries strive to adopt more responsible manufacturing practices, there is a growing preference for bioplastics and recycled materials in 3D printing applications. This shift is largely motivated by stringent environmental regulations and a rising consumer demand for sustainable products. In response, many companies are investing significantly in research and development to create innovative biodegradable plastics that maintain the performance standards of traditional materials while minimizing environmental impact. This commitment to sustainability not only aligns with corporate responsibility goals but also paves the way for new opportunities across industries such as healthcare and consumer goods, where eco-friendly solutions are becoming more sought after.

Gather more insights about the market drivers, restrains and growth of the 3d Printing Plastics Market

Drivers, Opportunities & Restraints

One of the primary drivers for the 3D printing plastics market is the expanding adoption of 3D printing technology in the healthcare sector. Medical applications, including custom prosthetics, implants, and surgical models, are increasingly leveraging the precision and adaptability offered by 3D printing. The plastics employed in these applications, such as polylactic acid (PLA) and polyether ether ketone (PEEK), provide the necessary flexibility and durability for medical devices. The surge in demand for personalized healthcare solutions, combined with ongoing advancements in biocompatible and high-performance plastics, is significantly propelling the market's growth. As the healthcare industry increasingly values patient-specific solutions, the role of 3D printing is expected to expand, enhancing the overall demand for specialized plastics.

Another significant opportunity for growth within the 3D printing plastics market lies in the automotive industry. Manufacturers are increasingly focused on reducing vehicle weight to improve fuel efficiency and adhere to stricter emissions regulations, making 3D printing an effective method for producing lightweight plastic components. The transition towards electric vehicles (EVs) further amplifies this demand, as lighter materials are crucial for extending battery life and enhancing overall vehicle performance. Companies that invest in developing innovative lightweight materials tailored specifically for automotive applications are well-positioned to capitalize on this emerging opportunity. The automotive sector's increasing reliance on advanced manufacturing techniques such as 3D printing will likely contribute to the market's accelerated growth in the coming years.

Despite its promising potential, the 3D printing plastics market faces several challenges that could impede its expansion. One of the most significant constraints is the high cost associated with 3D printing materials. Plastics with specialized properties—such as high heat resistance, biocompatibility, or specific mechanical strengths—often come at a premium compared to conventional manufacturing materials. Furthermore, the investment required for 3D printing equipment, coupled with the generally slower production speeds when compared to traditional mass production techniques, can render 3D printing less viable for large-scale manufacturing operations. This economic factor poses a particular challenge in cost-sensitive industries like consumer goods and packaging, where competitive pricing is essential for market success.

In summary, the global 3D printing plastics market is poised for substantial growth, driven by the rising demand for customized products, advancements in sustainable materials, and the growing adoption of 3D printing technology in sectors such as healthcare and automotive. However, the challenges related to material costs and production efficiency must be addressed to unlock the full potential of this rapidly evolving market. As industries continue to explore the capabilities of 3D printing, the development of innovative materials and cost-effective solutions will be critical in shaping the future landscape of the 3D printing plastics market.

Order a free sample PDF of the 3d Printing Plastics Market Intelligence Study, published by Grand View Research.