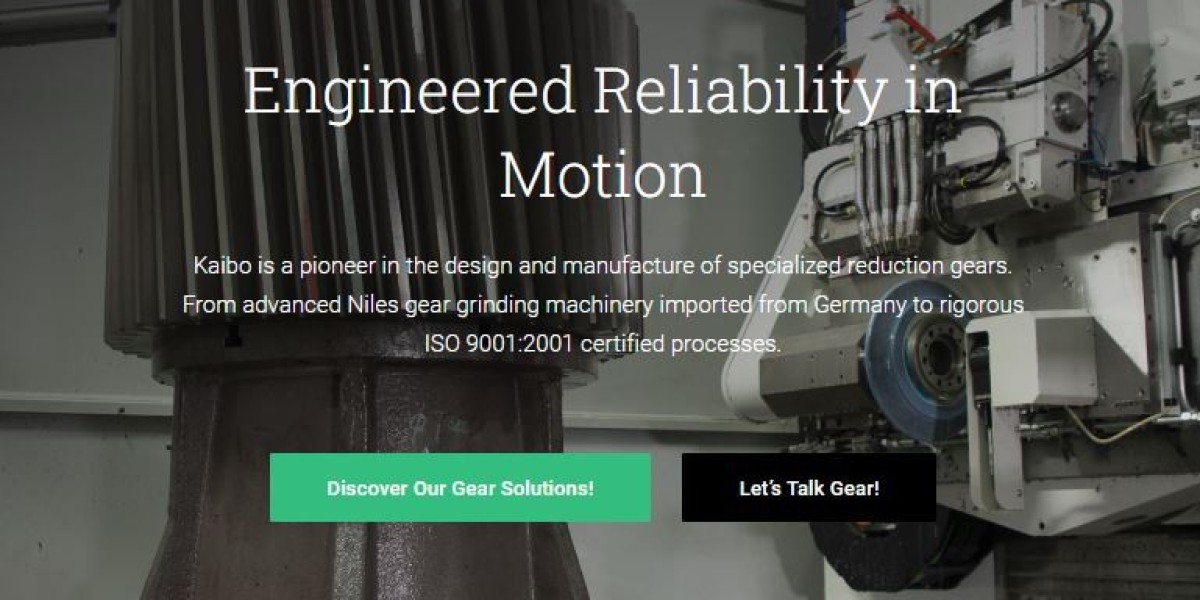

When it comes to industrial gearboxes, the significance of parallel shaft drives cannot be overlooked. These drives serve as the backbone for efficiently transferring power while maintaining a parallel orientation, ensuring seamless operations. Their role in handling high torque loads with ease and compact design makes them a preferred choice in various industries. The advantages and applications of parallel shaft drives are vast, offering a glimpse into the critical role they play in enhancing performance and reliability. Stay tuned to discover the intricate details of how parallel shaft drives revolutionize industrial gearbox functionality.

Functionality of Parallel Shaft Drives

Parallel shaft drives play a crucial role in the functionality of industrial gearboxes. These drives are essential components that transmit power from the input shaft to the output shaft, allowing for the necessary torque and speed adjustments within the gearbox. By maintaining a parallel orientation between the input and output shafts, parallel shaft drives efficiently transfer rotational motion to various mechanical components.

One key aspect of parallel shaft drives is their ability to handle high torque loads while maintaining a compact design. This feature makes them ideal for applications where space constraints are a concern. Additionally, the parallel shaft arrangement allows for easy maintenance and inspection of the drive components, simplifying troubleshooting and repair processes when needed.

Furthermore, parallel shaft drives are known for their durability and reliability in industrial settings. With proper lubrication and maintenance, these drives can operate efficiently for extended periods, contributing to the overall performance and longevity of the gearbox.

Advantages of Parallel Shaft Drives

When considering industrial gearboxes, one can't overlook the advantages that parallel shaft drives bring to the table.

Parallel shaft drives offer increased efficiency by transmitting power between parallel shafts, reducing energy loss through friction. This design also allows for a more compact gearbox size, making it suitable for applications where space is limited. Additionally, parallel shaft drives provide higher torque capacity compared to other drive systems, enabling them to handle heavier loads with ease.

Another key advantage of parallel shaft drives is their versatility in terms of speed ratios. They can be configured to achieve a wide range of speed ratios, making them adaptable to various industrial requirements. Moreover, parallel shaft drives are known for their durability and reliability, requiring minimal maintenance over their lifespan.

This reliability translates to cost savings in the long run, as fewer breakdowns and repairs are needed. Overall, the advantages of parallel shaft drives make them a popular choice for industrial gearbox applications.

Applications in Industrial Settings

Enhancing operational efficiency and performance in a variety of industrial settings, the utilization of parallel shaft drives in industrial gearboxes proves to be a strategic choice. These drives find applications in numerous industries, including manufacturing, automotive, mining, and food processing.

In manufacturing plants, parallel shaft drives are commonly used in conveyor systems, packaging equipment, and material handling machinery. The automotive sector benefits from these drives in assembly line equipment and robotic systems.

In mining operations, parallel shaft drives are essential components in crushers, conveyor belts, and hoists, enabling heavy-duty applications. Food processing plants rely on these drives for mixers, grinders, and packaging machines, ensuring smooth operations.

Performance Enhancement With Parallel Shafts

To optimize operational efficiency and boost performance in industrial applications, the integration of parallel shaft drives in gearbox systems offers a significant advantage. By utilizing parallel shafts, you can distribute the load across multiple gear sets, reducing individual gear stresses and enhancing overall system durability. This design feature allows for smoother power transmission, minimizing vibration and noise levels while increasing energy efficiency.

Parallel shaft drives also enable higher torque capabilities, allowing your machinery to handle heavier loads without sacrificing performance. This enhanced torque capacity is especially beneficial in applications where increased power output is required, such as in heavy-duty manufacturing processes or material handling equipment.

Furthermore, the parallel shaft configuration provides flexibility in design, making it easier to customize gearbox systems to specific operational requirements. This adaptability ensures that your machinery operates at optimal performance levels, meeting the demands of your industrial processes effectively.

Reliability and Optimization in Gearboxes

In optimizing gearbox systems for industrial applications, reliability and optimization play pivotal roles in ensuring seamless operations and long-term performance.

When it comes to the reliability of gearboxes, factors such as material selection, lubrication systems, and precision engineering techniques are crucial in minimizing wear and tear, reducing downtime, and extending the overall lifespan of the gearbox.

By implementing advanced optimization strategies like computer-aided design (CAD) simulations and performance testing, manufacturers can fine-tune gear tooth profiles, load distribution, and operational efficiency to enhance the gearbox's overall reliability and efficiency.

Additionally, predictive maintenance techniques, such as vibration analysis and oil condition monitoring, can help detect potential issues before they escalate, further improving the gearbox's reliability.

Frequently Asked Questions

Can Parallel Shaft Drives Be Used in Non-Industrial Applications?

Yes, parallel shaft drives can be used in non-industrial applications. They offer efficient power transmission in various settings like automotive, agricultural, and marine industries. Their versatility and durability make them suitable for a wide range of uses.

Are Parallel Shaft Drives Compatible With All Types of Gearboxes?

Yes, parallel shaft drives are not compatible with all types of gearboxes. It's essential to ensure compatibility for optimal performance. Check manufacturer specifications and consult experts if needed to guarantee a suitable match for your application.

What Are the Common Maintenance Issues With Parallel Shaft Drives?

Regular maintenance is crucial for parallel shaft drives. Make sure to check for lubrication levels, monitor for any unusual noises, and inspect for wear and tear on gears. Preventive care can help avoid costly repairs.

How Do Environmental Factors Affect Parallel Shaft Drive Performance?

In harsh environments, like extreme temperatures or high humidity, parallel shaft drive performance may deteriorate. Moisture can lead to corrosion, while temperature variations impact lubrication effectiveness. Regular inspections and appropriate maintenance help mitigate these issues and ensure optimal operation.

Can Parallel Shaft Drives Be Retrofitted Into Existing Industrial Machinery?

Yes, you can retrofit parallel shaft drives into existing industrial machinery. It's a viable option to upgrade performance. Consider consulting with experts for a seamless integration that aligns with your operational needs and maximizes efficiency.

Conclusion

Overall, parallel shaft drives are essential components in industrial gearboxes, providing efficient power transmission, compact design, and high torque capacity. Their advantages, including increased efficiency and reliability, make them invaluable in various industries like manufacturing, automotive, and mining. By optimizing performance and ensuring smooth operations, parallel shaft drives play a crucial role in enhancing the overall functionality and longevity of industrial gearboxes.