With the rapid advancements in electronics, computing, automotive, and industrial systems, effective thermal management has become critical to ensure reliable performance and longevity. Custom heatpipe manufacturers play a crucial role in designing advanced thermal solutions tailored to meet the specific needs of today’s high-power, compact devices. Here’s why partnering with a custom heatpipe manufacturer is essential for achieving optimal heat management in cutting-edge applications.

1. Tailored Solutions for Precise Thermal Requirements

Unlike standard heatpipes, custom heatpipes are designed with the exact specifications of the application in mind. A custom heatpipe manufacturer can optimize key parameters, such as shape, size, material, and working fluid, to meet specific thermal performance targets. Customization is especially valuable in applications with unique spatial or temperature constraints, where standard heatpipes may not fit or perform efficiently. By creating heatpipes that align with precise thermal requirements, manufacturers ensure devices can operate at peak efficiency while avoiding overheating or thermal throttling.

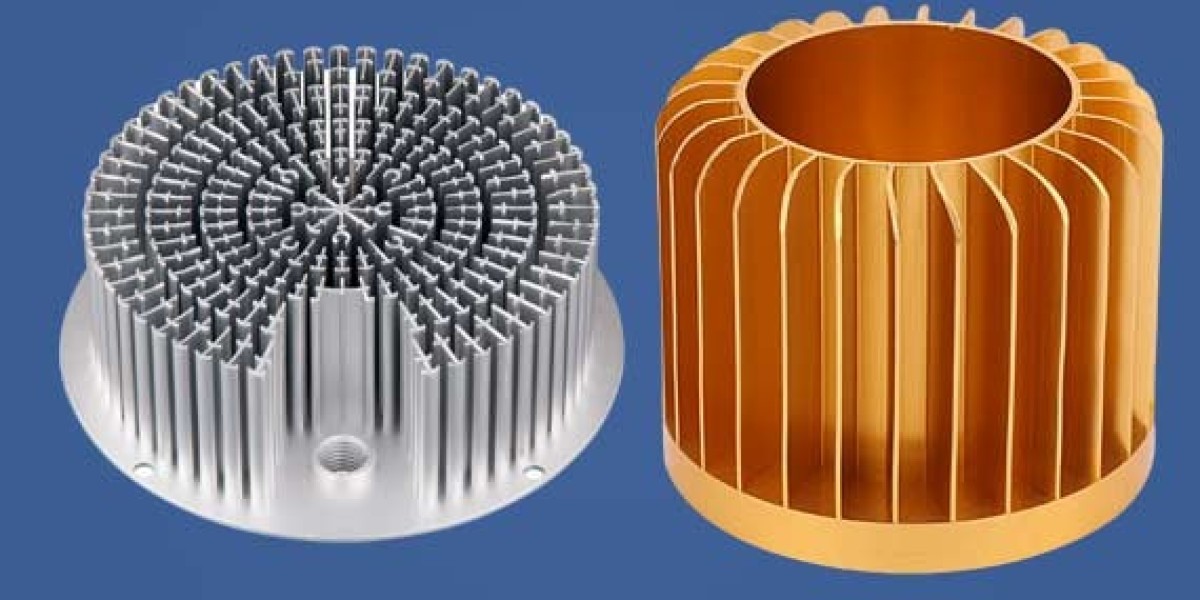

2. Enhanced Efficiency for Compact and High-Power Designs

As devices become smaller and more powerful, cooling requirements become increasingly complex. Custom heatpipe manufacturers excel at developing heatpipes that maximize heat transfer efficiency within compact spaces. This is achieved through advanced design techniques, such as optimizing the heatpipe’s wick structure, vapor chambers, and fin arrangements. These enhancements allow for efficient heat dissipation in devices with high power density, where traditional cooling methods may be inadequate. Custom heatpipes improve device performance and ensure reliability in environments where thermal management is a critical factor, such as in high-performance computing, gaming, and telecommunications.

3. Flexibility in Design for Complex Applications

Applications in sectors like aerospace, automotive, and industrial equipment often require thermal solutions that can withstand extreme conditions or adapt to unique configurations. Custom heatpipe manufacturers offer flexibility in design, enabling them to create heatpipes suited to complex or irregularly shaped components. This flexibility extends to options like bent or looped designs, high-temperature resistance, and specific mounting configurations. For example, in automotive applications, heatpipes may need to navigate tight spaces and work effectively in fluctuating temperatures. Custom manufacturers can deliver designs that meet these specific demands, ensuring optimal heat transfer regardless of application complexity.

4. Advanced Materials and Innovation in Thermal Technology

A key advantage of working with a custom heatpipe manufacturer is access to the latest innovations in materials and thermal technology. Custom manufacturers often invest in research and development to incorporate advanced materials like high-conductivity alloys or enhanced wicking structures that improve overall thermal performance. They also stay current with emerging technologies, such as hybrid heatpipes that combine phase-change and conduction methods, to address increasingly demanding cooling needs. By leveraging these innovations, custom heatpipe manufacturers provide solutions that not only enhance performance but also anticipate future thermal challenges.

5. Reliability and Longevity in Extreme Environments

For applications operating in harsh or extreme environments, durability is just as important as thermal efficiency. Custom heatpipe manufacturers can design heatpipes with reinforced structures, corrosion-resistant materials, and customized working fluids that withstand extreme temperatures, pressure changes, and chemical exposure. This attention to durability ensures that the heatpipes maintain their performance and structural integrity over time, reducing the risk of thermal-related failures. Industries such as military, aerospace, and heavy-duty manufacturing benefit greatly from the enhanced reliability and longevity that custom heatpipe solutions provide, helping reduce maintenance costs and downtime.

Custom heatpipe manufacturers are essential for advanced thermal solutions due to their ability to deliver tailored, efficient, and durable cooling components for a wide range of applications. Their expertise in designing heatpipes that meet precise thermal requirements, support compact and high-power devices, offer design flexibility, incorporate innovative materials, and withstand extreme conditions makes them invaluable partners in today’s technology landscape. For applications where effective thermal management is crucial, a custom heatpipe manufacturer provides the specialized knowledge and advanced solutions necessary to ensure optimal performance and reliability.