Introduction to Laurolactam Manufacturing

Laurolactam is a critical monomer used in producing nylon-12, a versatile polymer with applications in automotive, electronics, packaging, and consumer goods. This compound offers superior durability, chemical resistance, and flexibility, making it a preferred choice for high-performance materials.

Request a Free Sample – https://www.procurementresource.com/reports/laurolactam-manufacturing-plant-project-report/request-sample

Setting up a laurolactam manufacturing plant Project Report involves advanced chemical processes, significant capital investment, and adherence to stringent environmental and safety regulations. The plant's efficiency and profitability depend on a robust business strategy, reliable raw material procurement, and state-of-the-art technology.

Laurolactam and Caprolactam: Key Comparisons

While laurolactam is pivotal in nylon-12 production, caprolactam serves as the monomer for nylon-6. Both share similarities in their manufacturing processes and raw material requirements but cater to distinct market demands. A caprolactam manufacturing plant project report offers valuable insights into raw material dynamics, cost structures, and technological requirements, which can also be applied to laurolactam production.

Read Full Report With Table Of Contents – https://www.procurementresource.com/reports/laurolactam-manufacturing-plant-project-report/toc

Key Features of a Laurolactam Manufacturing Plant Project Report

Market Dynamics

- Global demand for nylon-12 across automotive, industrial, and consumer sectors.

- Growth drivers, such as lightweight materials in the automotive industry and increased use in high-performance applications.

- Regional trends impacting laurolactam supply and demand.

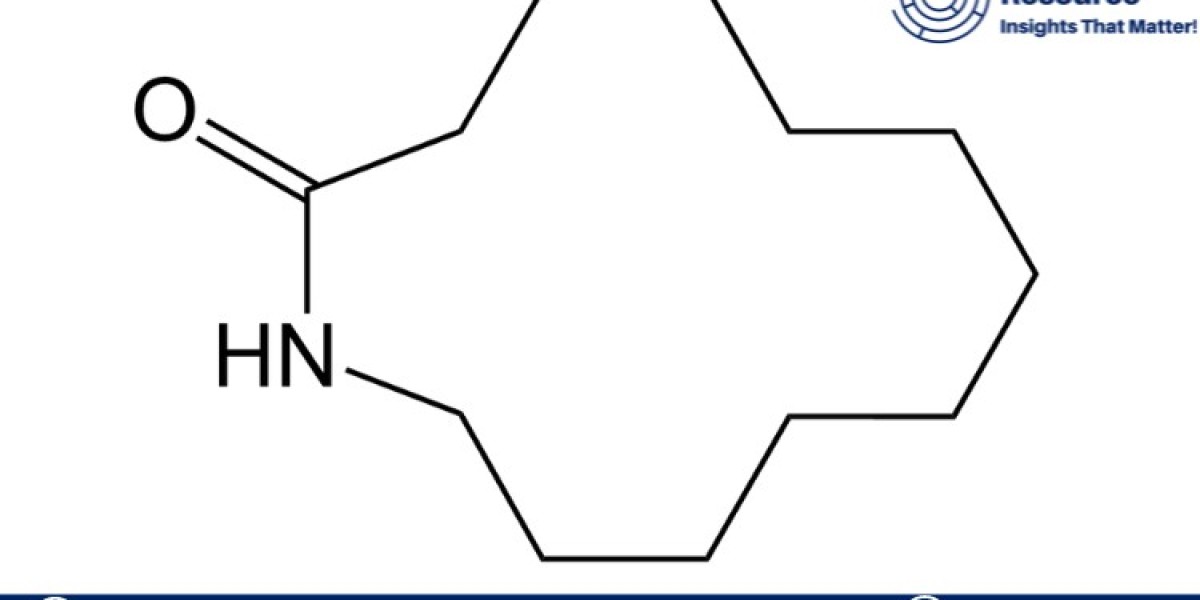

Manufacturing Process Overview

- Detailed chemical synthesis of laurolactam through lactamisation of ω-aminododecanoic acid.

- Advanced technologies to improve process efficiency and product quality.

- Key operational requirements, including temperature control, catalytic systems, and high-purity raw materials.

Raw Material Requirements

- Essential raw materials such as ω-aminododecanoic acid and related precursors.

- Supplier analysis for consistent quality and cost management.

- Logistics considerations for raw material procurement.

Cost Analysis

- Capital investment for plant setup, including equipment and infrastructure.

- Operational costs, including raw materials, utilities, labour, and maintenance.

- Profitability analysis and break-even point estimation.

Environmental and Safety Considerations

- Strategies to manage by-products and minimise environmental impact.

- Compliance with global and regional safety and environmental regulations.

- Adoption of sustainable practices, such as waste recycling and energy-efficient technologies.

Procurement Resource for Laurolactam and Caprolactam

Procurement is a cornerstone of any manufacturing operation. Key procurement resources for laurolactam manufacturing include:

- Raw Material Suppliers: Reliable sources for high-quality ω-aminododecanoic acid and other precursors.

- Technology Providers: Advanced machinery and process innovations to optimise production.

- Logistics Partners: Efficient transportation of raw materials and finished products.

- Regulatory Advisors: Ensuring compliance with safety and environmental standards.

For a caprolactam manufacturing plant project report, the procurement resources are similarly critical. Key raw materials like cyclohexanone, hydroxylamine sulfate, and ammonium sulfate require careful sourcing, quality control, and cost analysis.

Market Trends Impacting Laurolactam and Caprolactam Manufacturing

Increased Demand for Lightweight Materials The automotive industry is prioritising lightweight and durable materials, driving the demand for nylon-12 and nylon-6, boosting laurolactam and caprolactam production.

Technological Innovations Advancements in production technologies reduce waste and energy consumption, enhancing the overall efficiency of manufacturing plants.

Sustainability Focus Companies are increasingly adopting eco-friendly production methods, including waste recycling and the use of renewable energy, to meet regulatory and consumer expectations.

Regional Market Insights Asia-Pacific dominates laurolactam and caprolactam production due to its robust industrial base and growing automotive and electronics sectors. Europe and North America also play significant roles in these markets.

Applications of Nylon-12 and Nylon-6

- Automotive: Lightweight parts, fuel lines, and under-the-hood components.

- Electronics: Insulating materials and durable casings.

- Consumer Goods: Packaging, sports equipment, and fashion products.

- Industrial: High-performance coatings, adhesives, and 3D printing materials.

Procurement R#esource’s Role in Manufacturing Reports

Procurement Resource is a leading consulting firm that specialises in providing comprehensive project reports for various manufacturing industries, including laurolactam and caprolactam. Their reports feature:

- Market Analysis: Detailed insights into demand-supply dynamics and growth trends.

- Cost Breakdown: Comprehensive cost structures, including fixed and variable costs.

- Raw Material Insights: Supplier analysis and logistics considerations.

- Technological Guidance: Recommendations for state-of-the-art machinery and processes.

- Sustainability Guidance: Strategies for eco-friendly production and regulatory compliance.

Whether you are planning a laurolactam manufacturing plant or a caprolactam project, Procurement Resource offers tailored solutions to ensure successful project execution.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA